The Diesel Swirl Flap really can be one of the biggest threats to your engine. Quite simply, with a weak spindle which tends to fracture under carbon buildup and get sucked into the engine, the engine is at great risk of internal damage.

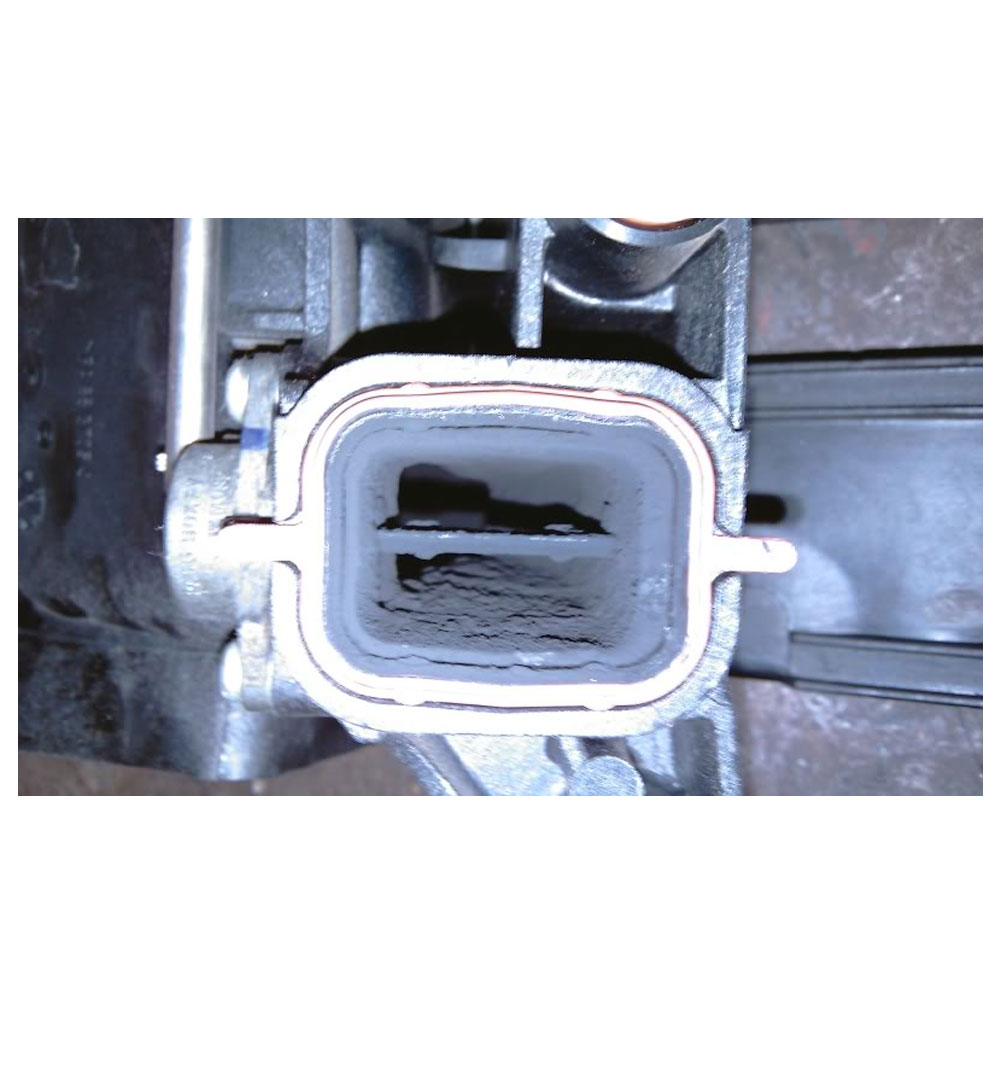

If the swirl flaps have caused a dtc problem due to carbon buildup preventing proper flap movement, the flaps can be decoked to restore function. In 75% of cases the cleaning will result in the flap function being returned to normal operation. The biggest drawback is that the flaps, their spindles and the driving motor(s) are weak and have a very high failure rate so reoccurance or wear and tear damage is likely.

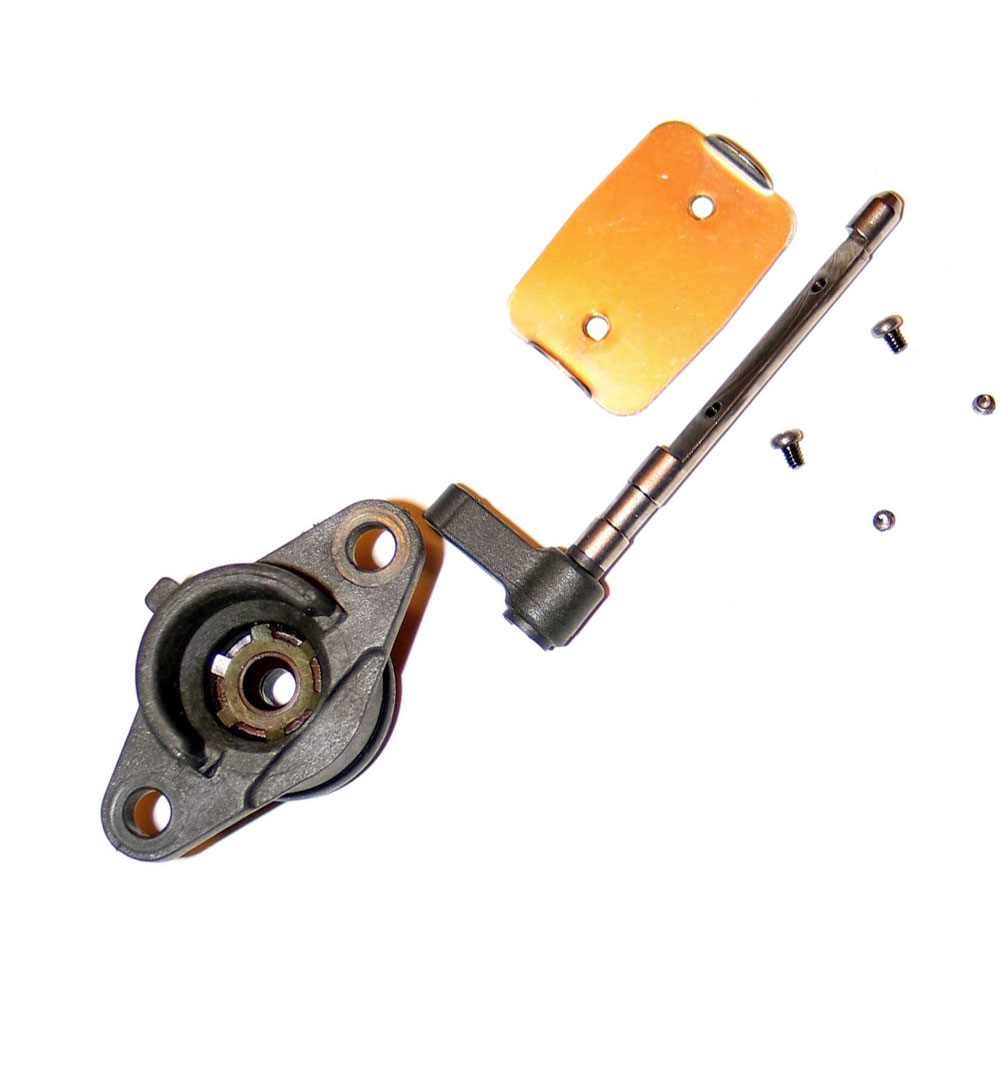

Renewal of the swirl flap system is another option. Usually aftermarket repair kits are available or there is the choice of genuine manufacturer new parts. Often the parts are available separately if suitable as well. Genuine swirl flap components may have a slighly improved longevity but we accept that the costs may be prohibitive, aftermarket options may also be available for some models.

The only permanent solution to the known issues is to remove the risk with complete bypass. Removing the flaps only affects emissions levels in a minor way at idle and the car will still easily be within MOT emissions regulations. We create blanking plates on site using our CAD controlled Plasma cutter, install them and remap your engine ECU software to eliminate the expected swirl flap operation. An effective and complete solution.

The BMW diesel engines produced between 2000 and 2008 all have a particular design problem with inlet manifold butterfly flaps (commonly known as swirl flaps). Swirl flaps are used inside the inlet manifold of the BMW M47TU & M57TU diesel engines to vary the length of inlet manifold tract subject to load and anticipated demand. This allows optimum performance to be delivered (on a dynamometer!)

Back in 2000, BMW/Pierburg made a decision to manufacture diesel engine with swirl flaps made from steel. BMW swirl flaps commonly fail in such a way that they either: drop an affixing screw and or the upper section of the spindle. If this does not stop the engine, the remaining swirl flap falling completely into the engine will!

The outcome of swirl flap failure is not pretty in the slightest. Diesel engine pistons cycle at a rate of at least 60 revs per minute, so an ingested metal piece falling off the butterfly flap will be slammed by the moving internal components. Most often, one or more pistons end up severely damaged, along with several valves, an injector and the cylinder head, with possible collateral damage spreading to the turbo as well!

In 2004 the swirl flaps supporting spindle was increased in size, along with the affixing screw diameter. This reduced the number of flap failures but did not eliminate it.

We've found vehicles up to 2007 fitted with the earlier design, so take no comfort from this redesign.

BMW removed the swirl flaps from M57 engines completly after 2007 on some engine models. The same apporach should be taken by ALL owners of M47 or M57 engines or you risk engine failure without warning.

Once swirl flaps are removed, voids of 22mm or 32mm are left in the manifold. These voids need to be sealed, which is where Dragon Auto Works comes in - blanking plates. This is the only professional fix for this problem.

Don't take our word for it, do a quick search for BMW Swirl Flap failure and discove the nightmare that awaits BMW M47 and M57 engine owners.